|

Day 0 |

|

Certified organic grains are washed and soaked overnight. |

|

|

Day 1 |

|

After the grain has been steamed by wood fire (about 45 minutes) it is removed from the cauldron, which is lined with a netted muslin sack for the steaming process.

|

|

|

(left) Removing the steamed grain from the cauldron.

(line drawing to right) Removing the steamed grain from wooden steamer in the traditional Tsujita miso shop, near Tokyo, during the early 1970’s. |

|

|

|

|

|

The steamed grain cooling down in one of the two cooling boxes. The grain needs to cool down to 112ºF before it can be inoculated with the spores of the mold, Aspergillus oryzae.

|

|

|

Spore powder of the mold, Aspergillus oryzae, is mixed with a small portion of the steamed grain (in this picture it is Barley). About 3 tablespoons of spore powder are used for 350 pounds of grain.

|

|

|

Sowing the koji: This is a sacred moment in miso making, the beginning of the long journey of fermentation, which for some varieties may last as long as three years. The inoculated sample is sown evenly over the "field" of grain in the cooling box. This is the equivalent of the agricultural process of sowing grain on the earth. In this case, the grain itself becomes the "ground" upon which the koji is sown. It is an agricultural process raised up, above the earth, into a higher realm of life processes.

|

|

|

Anni Elwell looking over cooking box filled with barley koji |

|

|

The inoculated grain, now rightly called koji, is placed into a large wooden box lined with a muslin cloth. This box is called the "crib". The old masters recognized that the koji at this stage was like a newborn baby. This photo is from 1984. Christian with daughter, Anni, and, in his arms, Isaiah, about to transfer koji from the cooling boxes into the crib. |

|

|

The koji will stay in the crib overnight. It goes into the crib at about 80ºF; by the next morning the temperature will be approaching 95ºF.

|

|

|

Day 2 |

|

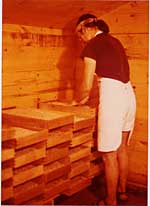

Morning of day 3: The koji is first stirred in the crib to oxygenate the growing mold while releasing carbon dioxide. Warmer and cooler areas of grain koji in the crib are mixed together. The grain is then removed from the crib and scooped by measured amounts into wooden trays. These "koji trays" are then stacked up in the koji room, a small incubation room heated to about 90ºF with high humidity. |

|

|

Koji trays stacked in first formation in koji room.

|

|

|

Later in the day the koji is stirred in each tray to disperse the up-building heat from the intense metabolic growth of the mold. The trays are re-stacked in a more open, "brick-lap" formation to allow more oxygen to nourish the koji and prevent overheating. The warmth given off by the koji is sufficient now to maintain the heat in the room. The koji itself at this stage and for the night following will be at 90 to 100ºF.

|

|

|

Trays stacked in koji room at end of day 2. (looking in from the production room).

|

|

|

Day 3 |

|

On day 3 the koji is ready to harvest. By this time, about 48 hours after it was initially steamed and inoculated, the grain is covered with a fragrant bloom of white mold.

|

|

|

The mycelia of the mold bind the grains together into a solid mass. During its growth, the mold has created vast stores of digestive enzymes, which are crucial to the second part of the fermentation process, when the salted koji is mixed with the cooked beans.

|

|

|

The chunks of koji are broken up by passing them through a screen. The crumbled koji is then mixed with a carefully measured amount of sea salt. The amount of salt used depends on the variety of miso and the intended length of fermentation. The sea salt preserves the enzymes and food value of the koji, while preventing any further mold growth. Salted koji is now ready to mix with cooked beans. |

|

|

|